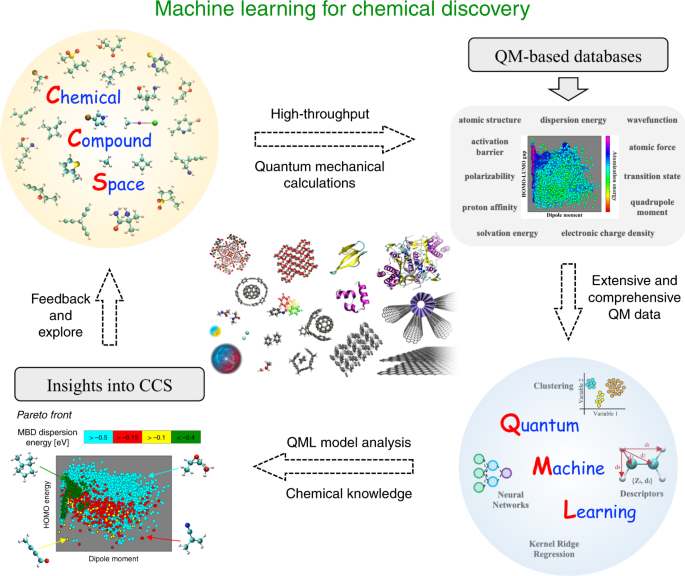

On the contrary, AI-based techniques have demonstrated their superb ability and have received much attention for chemical process modeling. In some cases, considering some assumptions such as physical properties’ constancy, ideality of gas phase and linearization of the nonlinear equations of the model is inevitable, which all impose limitations on the model leading to the reduction of the model’s robustness. Difficulties can arise from poor knowledge.

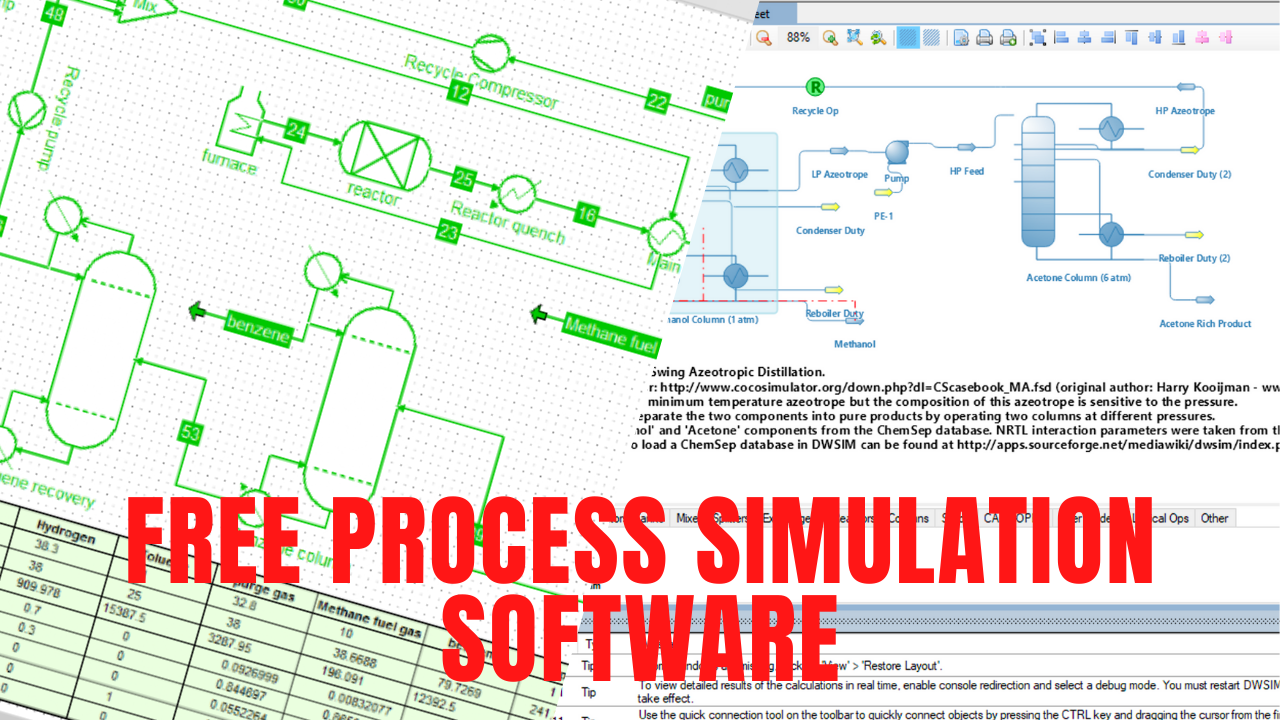

Moreover, a mechanistic model needs detailed knowledge and a lot of skill and ingenuity to incorporate the basic phenomena of the process in the model. Even if such a model has been developed, it might be impractical to solve or identify its parameters. Consequently, it is hard and sometimes even impossible to present them by mechanistic models. Due to the large number of variables affecting the process behavior and complex mathematical equations governing the system, many chemical processes are nonlinear and complicated. This approach contains algebraic and differential equations which involve mass, energy and momentum balances. In the mechanistic approach, fundamental physical and chemical laws, such as conservation laws, construct the basis of the model. Generally, There are two major types of modeling approaches in chemical engineering, namely, mechanistic (white box, first principle) and AI-based approach like ANN and fuzzy logic methods. Application of AI in chemical process modelingĬhemical process models which present the system behavior are useful in all phases of chemical engineering, from research and design to optimization and control and even plant operations. By choosing legal software, you will have an option to be guided by permanent and precious assistance of vendor's simulation experts, which is a great thing to start with.2.

#CHEMICAL PROCESS SIMULATION SOFTWARE COMPARISON SIMULATOR#

Please be aware of that before you decide to perform any operational changes based on simulator predictions.Ĭertainly, the best way to choose apropriate simulator is to contact software vendors and explain them the nature of your demands. If multiple chemical reactions are taking place in your system, it is very hard to define them by yourself and rely on simulation results. Some software packages have incorporated (built-in) models of unit operations (NH3 synthesis, TEG gas dehydration, Catalytic reformer, FCC, DHT etc.), which is the best way to perform various simulations of your process, if the model has been properly calibrated by experts. What is the advantage/disadvantage of each simulator, based on your demands? What type of simulation you want to perform? Unit material balance, chemical reactions, separation processes, equipment performance evaluation etc.Ģ. RefSYS, for example, is the best modeling tool for refinery services, side by side with KBC's Petro-SIM. It has a wide spectrum of different applications. Generally, Aspen software stands for one of the best engineering tools in process simulation area. Tell us ALL of the background and story behind this query and perhaps we can help when we are given more knowledge about what is going on here.Īnother issue is the fact that there is a lot of simulator pirating and illegal copies that are being sold/bartered/distributed in many places outside the USA - especially in the Far East. So how can an answer be taken seriously? It can't. So why worry about it? You haven't even specified what kind of process(es) it is that you will be simulating. Administrators run Universities, not Students.Īs a student, you are not knowledgeable or skilled enough to know the strengths and weaknesses of each one of the Simulators out in the market place. Your professors or instructors will issue (if they have the authority and means) you the use of a simulator program of their choosing and selection. Are you an independent millionaire who "dabbles" in simulators? Or are you just toying with an academic question that is beyond your resources and empowerment at the moment?Īs a student, you have practically no decision to make. You are, I suppose, a student and yet you are debating the difference between two major Simulation programs - one of which costs in the range of $30,000 -$50,000 a year, depending on its use and "bells & whistles". There is no practical, serious answer to your queries.

Your question is vague and hinges on general terms.

0 kommentar(er)

0 kommentar(er)